What is Psychrotrophic bacteria?

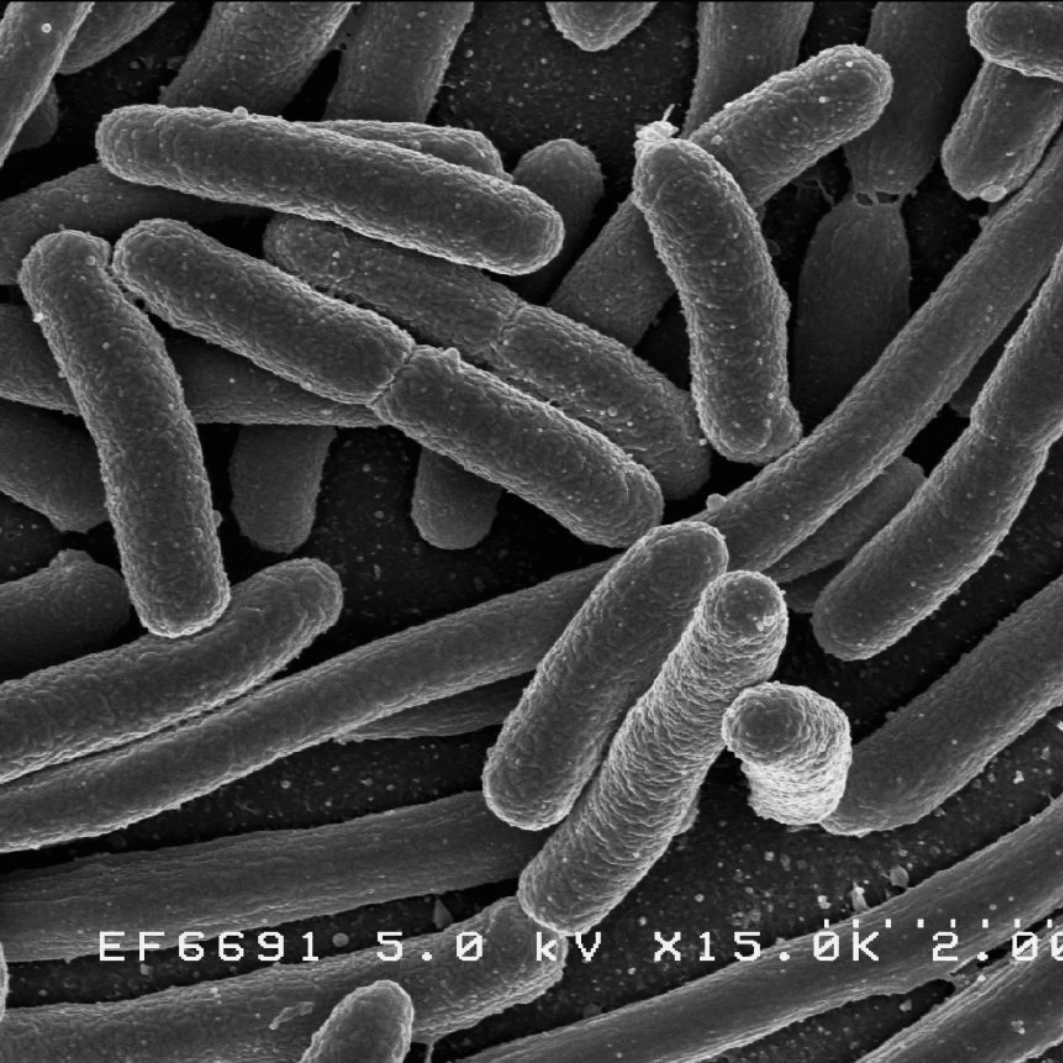

Psychrotrophic bacteria are a group of microorganisms that have the ability to grow and multiply at low temperatures, such as those found in refrigerated environments. Therefore, these bacteria can be a significant concern for the food industry, particularly in dairy products. While pasteurization effectively eliminates many harmful microorganisms, psychrotrophic bacteria are resilient and can still thrive in milk and other dairy items if introduced post-pasteurization through cross-contamination

How does this affect you

Psychrotrophic bacteria are the leading cause of spoilage in pasteurized milk, drastically reducing its shelf life. These bacteria produce enzymes that break down proteins, leading to curdling, off-flavors, and a shorter shelf life. As a result, consumers may experience undesirable textures and tastes, ultimately leading to wasted products and potential financial losses for dairy producers.

Did you know?

Even at contamination levels as low as a single psychrotrophic bacterium per liter, milk can develop quality defects.

How is it Detected

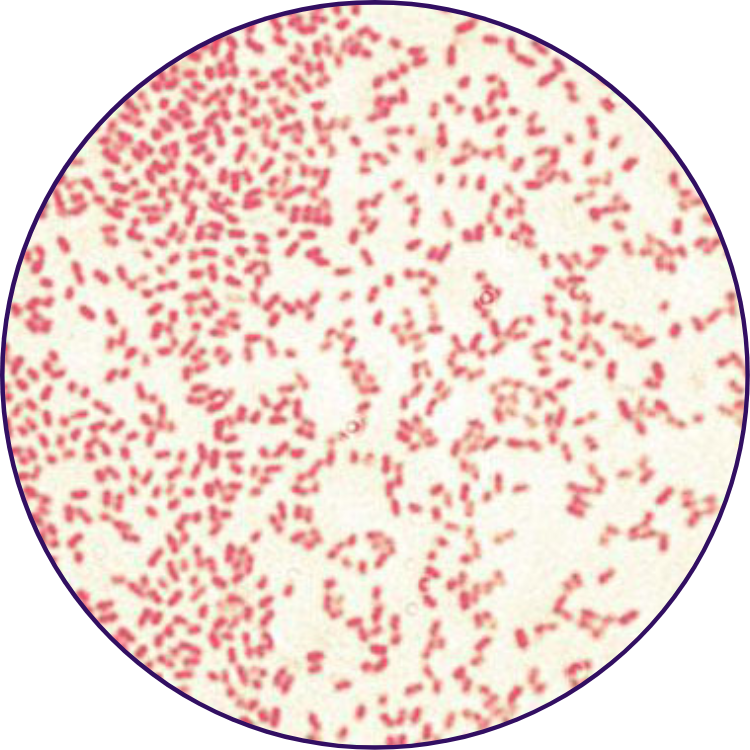

Detecting psychrotrophic bacteria requires a specialized incubation and testing process. Aseptically collected milk samples (10mls) from the pasteurizer are incubated at 7°C (45°F) for 10 days to allow bacterial growth. After incubation, a standard plate count is conducted, and samples exceeding 1,000,000 bacteria per milliliter are subjected to gram staining. If the bacteria are gram-positive, they are likely heat-resistant psychrotrophs, indicating potential contamination and spoilage risks in the milk supply.

How can we help?

PsychroFast is a quick and affordable test that can detect psychrotrophic bacteria in raw milk within just 30 hours. It works by using a selective agent to allow only gram-negative bacteria to grow. As these bacteria multiply, a color-changing indicator signals their presence, making contamination easy to detect. This is a major advantage for the dairy industry, as traditional methods can take much longer. Early detection means processors can act fast to prevent spoilage, improving milk quality and extending shelf life. By identifying contamination sooner, dairy producers can reduce waste, maintain consumer trust, and ensure their milk stays fresh for longer.

sales@fmcgis.com.au

Phone

1300 628 104

Location

Factory 11A, 1-3 Endeavour Road Caringbah NSW 2229